Products

Research & Development for Inhouse Program

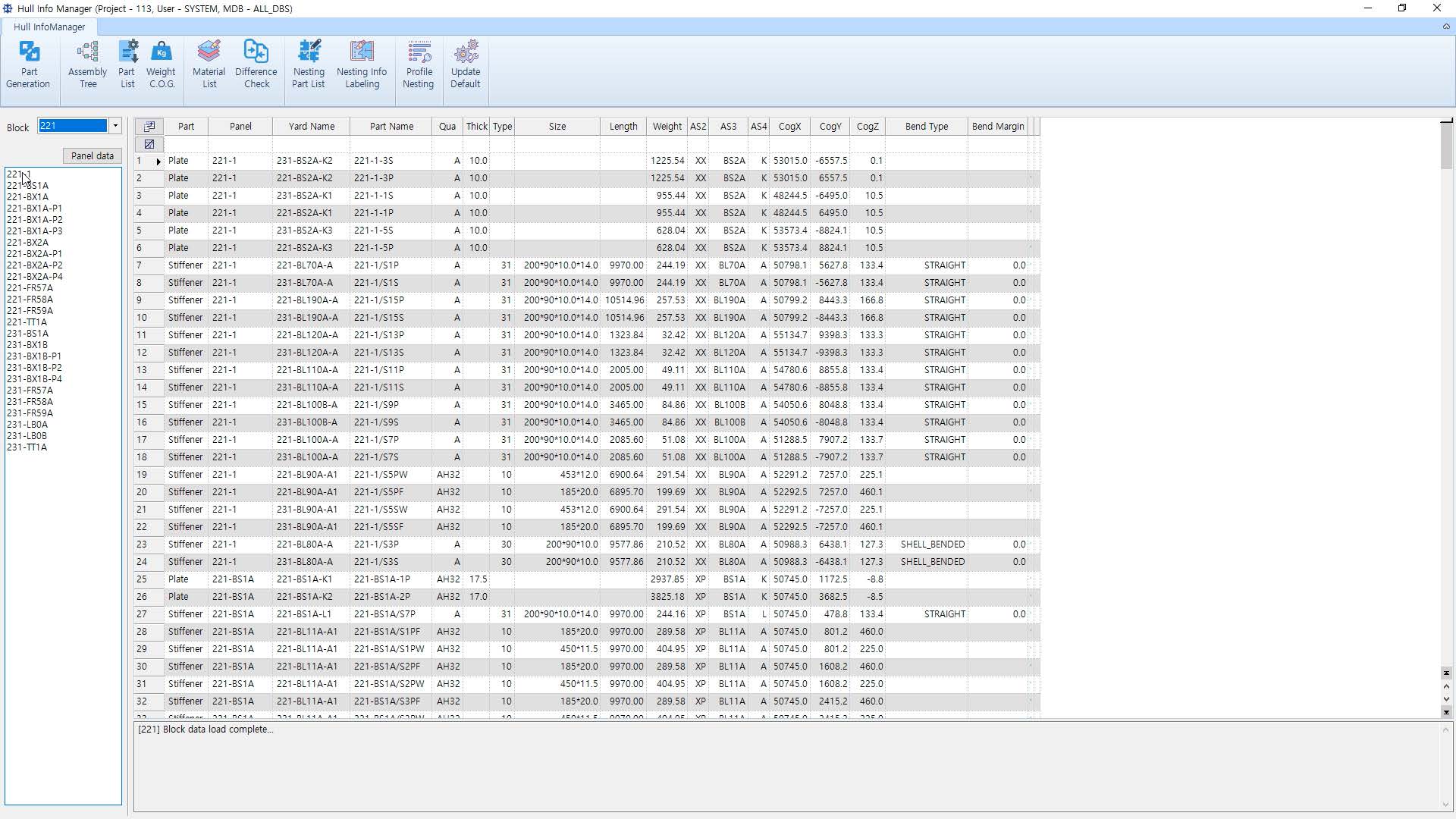

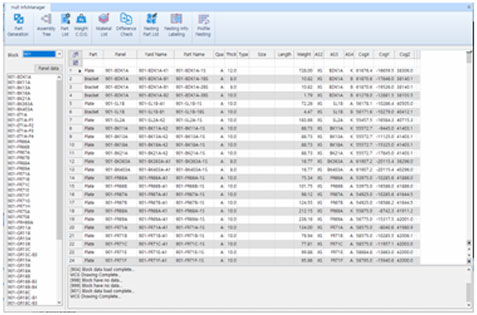

Hull Info Manager

- See Other Piping Products

- Programs Provided

- Features

- Benefit

- UI

- 사용고객사

Programs Provided

AVEVA MARINE

AVEVA MARINE

Programs Provided

AVEVA MARINE

AVEVA MARINE

Features

Features

- 1. Convenient user interface

- 2. Fast and easy sub-material extraction

- 3. Easy sub-material sorting by search term

- 4. Fast and convenient assembly tree editing

- 5. Convenient production of quantity information on sub-material and materials in Excel

- 6. Automatic creation of assembly weight and plate nesting drawings

- 7. Profile auto nesting and editing features

- 8. Convenient production of profile nesting and profile detail drawings

- 9. Comparative checking of model quantity and drawings and report creation features

- 10. Convenient project management using the administrative interface

-

-

Cost Reduction

- Improved productivity with increased work speed

-

-

Improved Work Efficiency

- Enhanced convenience with minimal touchups

- Convenient use based on an interface for each work process for the hull

- Reduced time by creating BOM files automatically

- Improved productivity with automatic production of hull nesting drawings

- Increased efficiency and consistency based on comparative checking of model quantity and drawing quantity

- Easily managed by the administrator

Benefit

Benefit

Program Function

Program Function

-

Part Generation

Part Generation enhances work efficiency by facilitating extraction of sub-material from hull modeling and creation of a list -

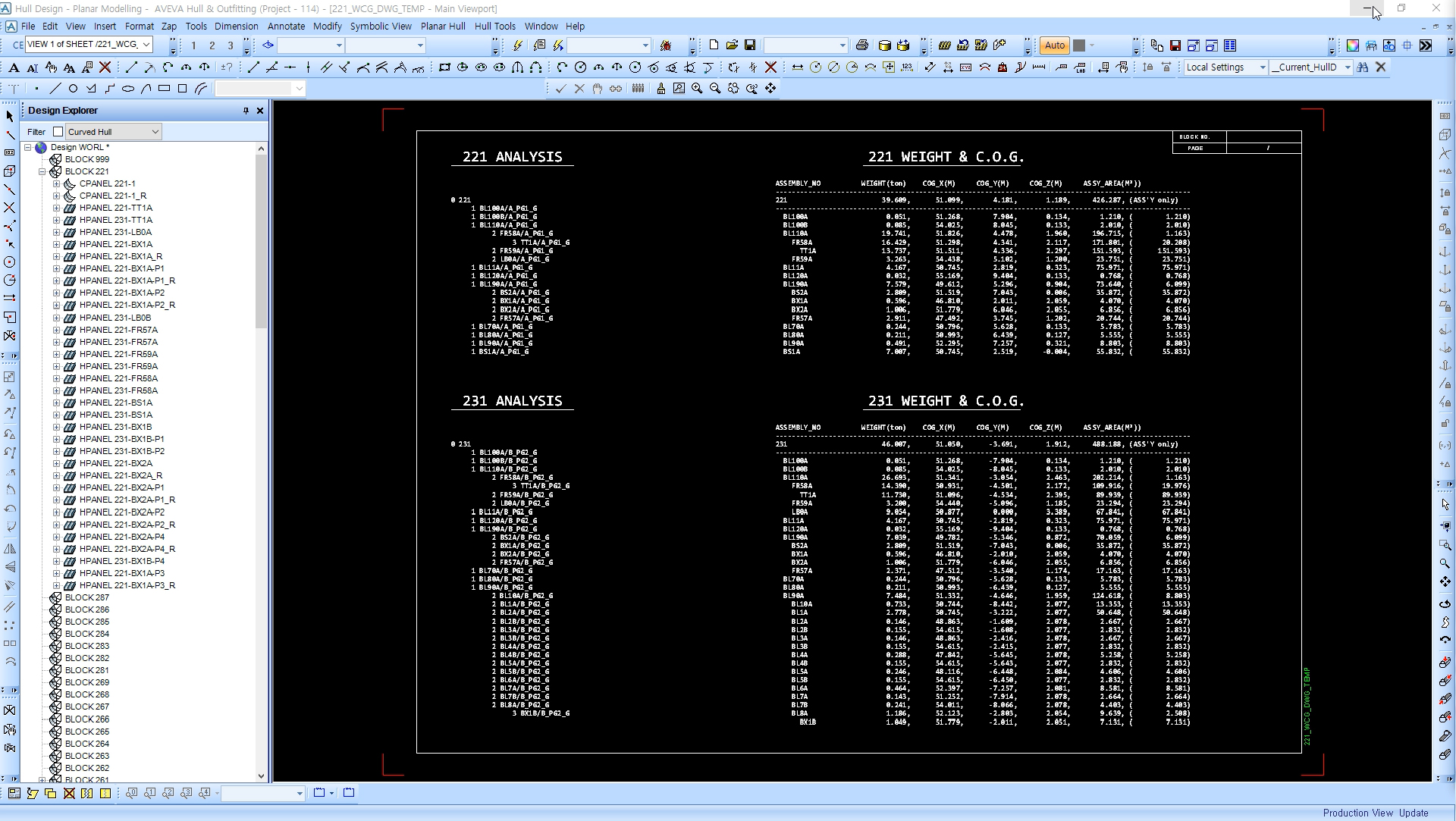

Weight C.O.G

Weight C.O.G. reduces the work time by automatically creating drawings in the form of trees by aggregating weight for each assembly -

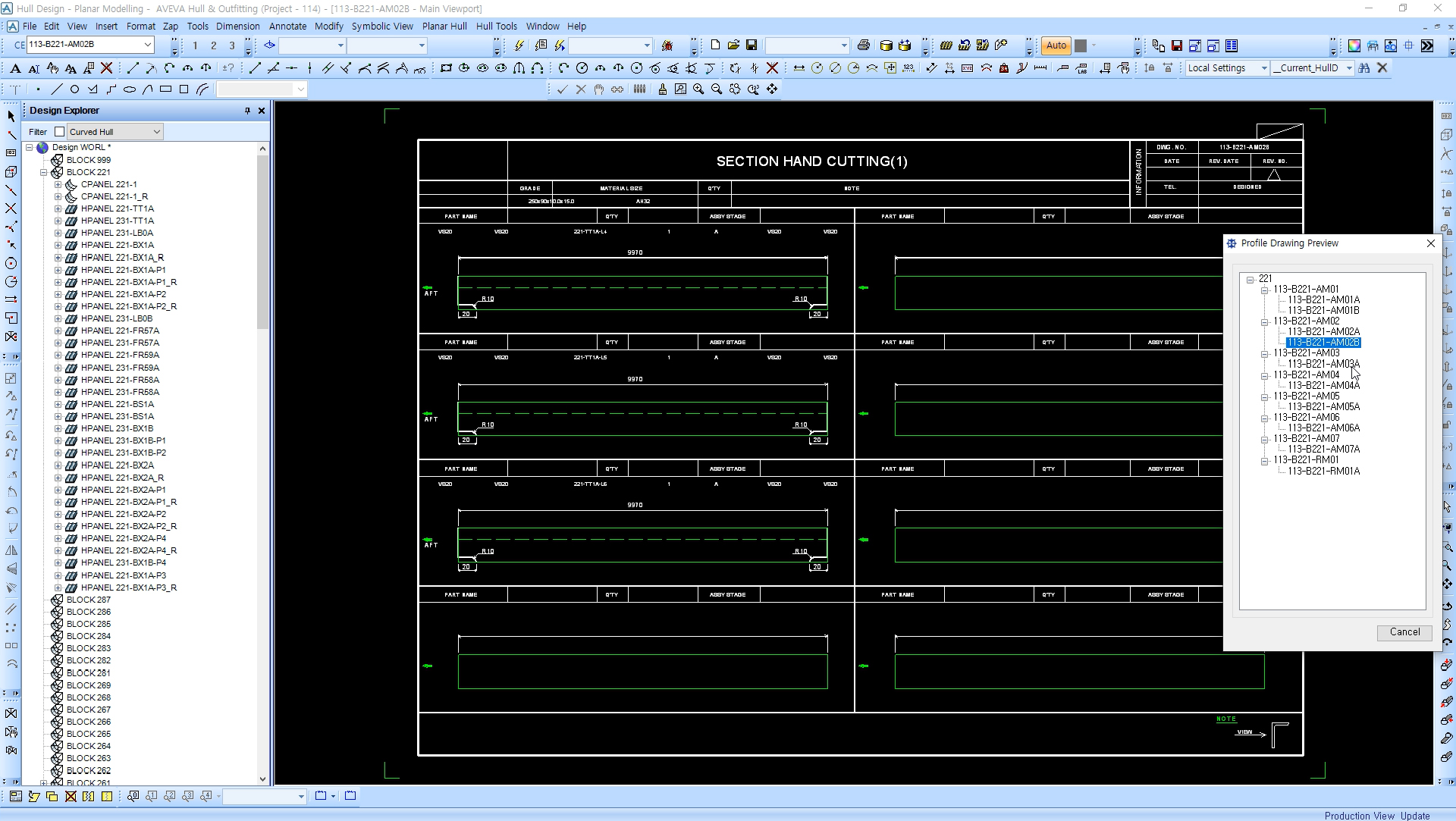

Nesting Info Labeling

Nesting Info Labeling enhances consistency and reduces work hours by automatically creating drawings with respect to each nesting after it is created -

Profile Nesting

Profile sub-material are automatically arranged by auto nesting and profile nesting drawings are automatically created using the drawing creation feature once the nesting is completed with efficiency based on enhanced ease of editing -

Option

Options to help the administrator configure appropriate settings based on related explanations provided via the UI

-

Assembly Tree

Assembly Tree allowing the user to edit the sub-material assembly extracted in Part Generation in the form of a tree by automatic aggregation so that the hull assembly can be configured with convenience -

Difference Check

Difference Check calculates the modeling sub-material quantity and their quantity according to the drawings for an automatic comparative analysis of the quantities and information to produce a report on the differences for the user to recognize and make the necessary changes -

Part List

Part List automatically aggregates the sub-material quantity and weight for each assembly and outputs the data in the form of an Excel file so that the user can check and use the information, thereby raising work efficiency -

Material List

Material List automatically aggregates the sub-material used in plate nesting and profile nesting and outputs the data as an Excel file so that the user can check and use the information, thereby improving work efficiency -

Nesting Part List

Nesting Part List automatically extracts sub-material for which plate nesting is possible and creates a report in the form of an Excel file for the user as a way to improve work efficiency

Main UI

Main UI